T5 LED Light Box Profile Roll Forming Machine z hydraulicznym biciem / strzyżeniem

LED Light Box Profile Roll Forming Machine (T5 Profile): W pełni automatyczna produkcja profili metalowych w celu oszczędności kosztów

Jeśli chcesz zastąpić tradycyjne profiły aluminiowe lub plastikowe LED z bardziej opłacalnymi alternatywami metalowymi, naszMaszyna do formowania profili w rolkach z pudełkiem świetlnym LED (specyficzna dla profili T5)Zaprojektowana do automatycznej produkcji seryjnej, ta maszyna wytwarza wysokiej precyzji aluminium, metalu,lub profile materiału na zamówienie ̇ obniżenie kosztów materiału przy jednoczesnym utrzymaniu stałej jakości dla produkcji pudełek świetlnych LED.

Po co wybierać profile metalowe poprzez formowanie rolkami?

W przeszłości profile pudełek świetlnych LED opierały się na odlewanym aluminium lub tworzywie sztucznym, które często wiązały się z wyższymi kosztami produkcji.Profile metalowe w zwojachdla dwóch kluczowych korzyści:

- Obniżenie kosztów: W procesie formowania rolki zużywa się mniej odpadów materiałowych i usprawnia produkcję, obniżając ogólne koszty jednostkowe w porównaniu z odlewaniem lub formowaniem tworzyw sztucznych.

- Elastyczność materialna: maszyna pracuje z aluminium, różnych metali lub innych kompatybilnych materiałów, pozwalając wybrać opcję najlepiej odpowiadającą Twojemu budżetowi i wymaganiom wydajności.

Przygotowaliśmy szczegółowe profile rysunkowe (w tym profil A) do Twojej referencji. Skontaktuj się z nami, aby zobaczyć, w jaki sposób gotowe profile metalowe są zgodne z Twoimi projektami pudełka świetlnego LED.

Pełna konfiguracja maszyny: od odwijania do przyjmowania

Maszyna do formowania rolki profilowej LED Light Box integruje wszystkie niezbędne komponenty do automatyzacji od końca do końca, zapewniając płynną, nieprzerwaną produkcję.

- Decoiler z maszyną do wyrównania: rozwija cewki surowca i wyrównuje blachę metalową w celu wyeliminowania zmarszczek, tworząc podstawy do precyzyjnego formowania.

- System przebijania otworów: Obsługa tworzenia otworów (krytyczne dla montażu pudełka świetlnego LED) z elastycznym czasem: niektóre otwory można przebićprzedtemWyroby z tworzyw sztucznychpokształtowanie ̇ dostosowanie do wymogów projektowania profilu.

- Główna maszyna do formowania walcowania: Serce systemu, kształtowanie arkuszy metalowych w profile T5 lub specjalne pudełka świetlne LED za pomocą precyzyjnych walców.

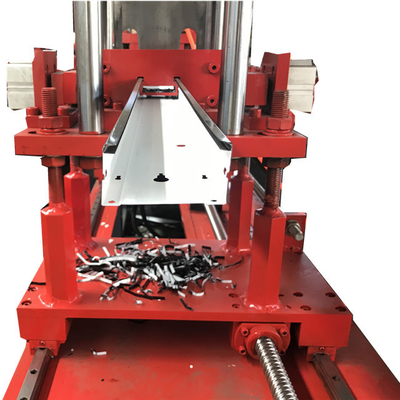

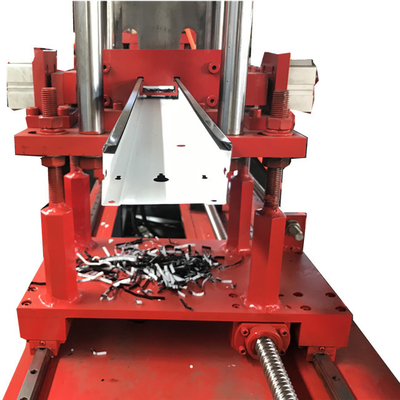

- System hydraulicznego strzyżenia: Wycinanie gotowych profili do pożądanej długości z wysoką dokładnością, minimalizując marnotrawstwo materiału.

- Tabela odbioru: gromadzi gotowe profile, gotowe do pakowania lub kolejnych etapów montażu.

Kluczowe parametry techniczne: Gwarancja precyzji i stabilności

Każdy element maszyny jest zaprojektowany w taki sposób, aby zapewniał dokładność, trwałość i wydajność pracy.

1Materiał i wydajność produkcji

| Parametry |

Szczegóły |

| Gęstość materiału produktu |

0.3 mm (optymalizowane pod kątem sztywności i masy profilu pudełka świetlnego LED) |

| Szerokość materiału produktu |

Dostosowywalne (ostatnia szerokość określona podczas uruchamiania na miejscu) |

| Szybkość formowania produktu |

2~8 m/min (regulowane za pomocą sterowania częstotliwością, aby odpowiadać potrzebom wyjściowym) |

| Błąd długości produktu |

±1 mm/3 m (wysoka precyzja w celu zapewnienia spójnego ustawienia profilu) |

| Całkowita moc urządzenia |

13kw |

| Zasilanie |

- Wyposażenie: 380V AC, 50Hz, trójfazowe

- Moc sterowania: AC 220V, 50Hz, jednofazowa (przystosowalna) |

2Główne specyfikacje komponentów

| Składnik |

Parametry |

| Serwozadostówka |

- Grubość karmienia: 0,3-1,5 mm

- Silnik napędowy: 1,5 kW

- Dokładność podawania: ± 0,1 mm (zapewnia precyzyjne wyrównanie materiału) |

| Maszyna do bicia hydraulicznego |

- Tonaż pieczętowania: 10t * 2 cioski (zarządza otworami dla różnych pozycji profili)

- Materiał do drukowania: Cr12MoV (wysoka odporność na zużycie, długa żywotność druku) |

| Ramy maszyn do formowania |

- Konstrukcja: Integralne spawanie rur kwadratowych (80x80mm)

- Płytka boczna: stal 25 mm Q235 (silna nośność do stabilnego formowania)

- Przewodnik żywienia: konstrukcja płyty przewodniczej (zapobiega odchyleniom materiału) |

| Wykonanie walcowników |

- Ilość: 22 grupy kół kołowych + 6-kołowy mechanizm wyprostowania (poprawiony kształt i prostotę profilu)

- Materiał: stal Cr12 (przetworzona i ugasiona, twardość HRC58-60°C dla odporności na zużycie)

- Główny wał: Φ38mm (wygaszony i hartowany pod kątem wytrzymałości)

- łożysko wału głównego: 6206 (na płytę boczną, płynne obrót) |

| Główny napęd maszyny |

- Silnik: 4kw (regulacja prędkości zmiennej częstotliwości)

- Reduktor: 4# reduktor cykloidalny

- Przesyłka: silnik → cykloidalny kołnierz reduktor → przekładnia łącza → synchroniczne obracanie kół kształtujących |

| Wyroby do obróbki włókien |

- Moc silnika hydraulicznego: 2,2 kW

- Tryb wyłączenia: wyłączenie + hydrauliczne wyłączenie

- Grubość ostrza: 3 mm (czyste, bez grzybów cięcia) |

3Elektroniczny system sterowania

System sterowania maszyną wykorzystuje zaufane, wydajne elementy, aby zapewnić stabilną pracę:

- Inwerter: Niezawodna marka zapewniająca płynną regulację prędkości.

- PLCJaponia Panasonic (dokładna kontrola programu dla wszystkich procesów).

- Ekran dotykowy: Taiwan Vinylon (intuicyjna obsługa, łatwe ustawienie parametrów).

- Pozostałe części elektryczne: Schneider (globalny lider w dziedzinie bezpieczeństwa elektrycznego, zmniejszający ryzyko awarii).

Wyświetlanie profili i obsługa maszyny

Przygotowaliśmy fizyczne próbki profili skrzynki świetlnej LED w kształcie rolki (w tym profili T5) oraz szczegółowe wideo robocze przedstawiające cały proces produkcji maszyny,od odwijania i bicia do formowania i obcinaniaSkontaktuj się z nami, aby poprosić o te zasoby i zobaczyć, jak maszyna pasuje do Twojego przepływu pracy.

Dostosować do potrzeb profilu LED

Niezależnie od tego, czy potrzebujesz regulować wymiary profilu, modyfikować pozycje otworów, czy dostosować się do różnych typów materiałów, możemy dostosować maszynę do Twojego konkretnego projektu pudełka świetlnego LED.Więcej szczegółów dotyczących parametrów, aby zobaczyć profile rysunków, lub omówić dostosowanie, skontaktuj się z naszym zespołem w dowolnym momencie. Jesteśmy tutaj, aby pomóc zoptymalizować linię produkcji profilów LED.

Twoja wiadomość musi mieć od 20 do 3000 znaków!

Twoja wiadomość musi mieć od 20 do 3000 znaków! Proszę sprawdzić email!

Proszę sprawdzić email!  Twoja wiadomość musi mieć od 20 do 3000 znaków!

Twoja wiadomość musi mieć od 20 do 3000 znaków! Proszę sprawdzić email!

Proszę sprawdzić email!